What is a Tevo Tarantula Case?

A Tevo Tarantula case, often referred to as an enclosure, is a protective structure designed to surround your Tevo Tarantula 3D printer. This case serves multiple crucial functions, enhancing the 3D printing experience and the quality of your prints. Think of it as a custom-built home for your printer, offering benefits that go beyond mere aesthetics. The case is typically constructed from materials like acrylic, polycarbonate, or even custom-built options, depending on your specific needs and preferences. It’s important to understand that a well-designed case is not just an accessory; it’s an investment in the longevity and performance of your 3D printer. The right case can significantly improve your printing results, especially when dealing with materials prone to warping or requiring specific temperature control. The Tevo Tarantula case is an essential component.

The Benefits of a Tevo Tarantula Case

Investing in a Tevo Tarantula case brings a wealth of advantages to the 3D printing enthusiast. These benefits translate directly into improved print quality, a safer working environment, and a more pleasant user experience. A case helps create a more stable printing environment, protect the printer from external factors, and offers greater control over the printing process. By mitigating environmental variables, a case allows your Tevo Tarantula to consistently produce high-quality prints, regardless of the ambient conditions. This is particularly important when printing with materials like ABS, which are very sensitive to temperature fluctuations. Beyond print quality, an enclosure helps to reduce noise, contains potentially harmful fumes, and enhances the overall safety of your setup. These advantages collectively make the Tevo Tarantula case an indispensable tool for both beginners and experienced 3D printing enthusiasts alike.

Improved Print Quality

One of the primary benefits of a Tevo Tarantula case is the significant improvement in print quality. Enclosures help to maintain a consistent internal temperature, crucial for preventing warping and layer separation, particularly with materials such as ABS. The case creates a more stable thermal environment, minimizing drafts and temperature fluctuations that can negatively impact the printing process. This consistent temperature distribution allows for better adhesion between layers, leading to stronger, more precise prints. By regulating the temperature, the case also helps to control the cooling rate of the printed material, reducing the likelihood of warping and other common printing defects. With a Tevo Tarantula case, you can consistently achieve higher-quality prints with reduced defects and improved dimensional accuracy, regardless of the ambient conditions.

Reduced Noise and Odor

Besides enhancing print quality, a Tevo Tarantula case also contributes to a more comfortable and safer working environment by reducing noise and containing odors. 3D printers, especially when operating, can generate significant noise levels, which can be distracting and disruptive. An enclosure acts as a sound barrier, significantly reducing the noise produced by the printer’s motors and fans. Furthermore, during the printing process, especially with certain materials like ABS, the printer can emit potentially harmful fumes. A well-designed case helps to contain these fumes, protecting the user from exposure. Some cases even come equipped with filters to further purify the air, making your 3D printing setup both quieter and healthier. By mitigating noise and containing odors, the Tevo Tarantula case ensures a more pleasant and safer printing experience.

Enhanced Safety

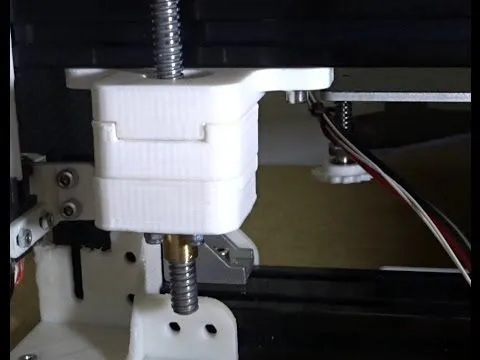

Safety is a paramount concern when operating any 3D printer, and a Tevo Tarantula case significantly enhances the overall safety of your setup. Firstly, the enclosure acts as a physical barrier, preventing accidental contact with hot components such as the heated bed or extruder nozzle, thereby reducing the risk of burns. Secondly, the case helps to contain any potential hazards associated with the printing process. In the event of a thermal runaway or a print failure that could cause the material to ignite, the enclosure can help to contain the fire, preventing it from spreading. Additionally, the enclosure creates a controlled environment, minimizing the risk of electrical hazards. By containing potential hazards and providing a protective barrier, the Tevo Tarantula case makes your 3D printing experience much safer and more secure for both you and those around you.

Top 7 Facts About Tevo Tarantula Case

- Temperature control is critical for print success, especially with materials like ABS.

- Cases reduce noise pollution, creating a quieter workspace.

- Enclosures help to contain potentially harmful fumes from certain printing materials.

- They protect the printer from dust, debris, and external impacts.

- Cases can improve layer adhesion, resulting in stronger prints.

- Enclosures offer a professional look and feel to your 3D printing setup.

- A well-designed case can extend the lifespan of your 3D printer.

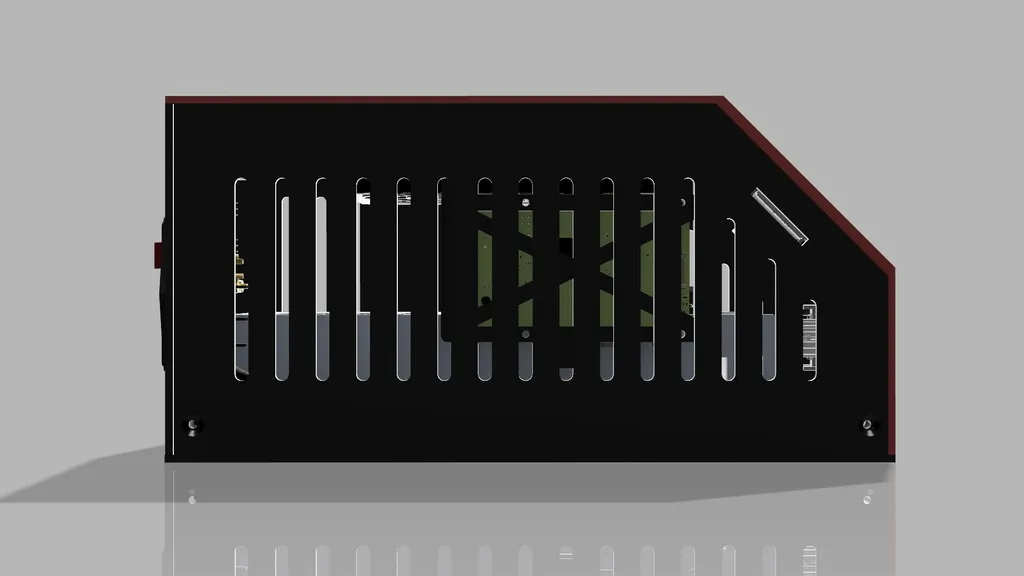

Case Material and Design Considerations

Choosing the right material and design for your Tevo Tarantula case is crucial for maximizing its effectiveness and ensuring it meets your specific printing needs. The material will determine the case’s thermal properties, durability, and overall appearance, while the design will affect its ease of use and functionality. You can find cases made from a variety of materials, from clear acrylic, offering a good balance of visibility and thermal insulation, to polycarbonate, known for its impact resistance and high-temperature tolerance. The design of the case should take into account factors like accessibility, ventilation, and ease of assembly. Considering these aspects will not only enhance the overall performance of your 3D printing setup but also ensure a more user-friendly and visually appealing enclosure.

Material Choices

Selecting the appropriate material for your Tevo Tarantula case depends on your priorities and printing requirements. Acrylic is a popular choice due to its transparency, allowing you to easily monitor your prints, and its relatively good thermal insulation properties. However, it can be prone to scratching and may not be as resistant to high temperatures. Polycarbonate is another excellent option, offering superior impact resistance and higher heat tolerance, making it ideal for printing materials that require elevated temperatures. It’s also more durable than acrylic, providing a longer lifespan. Other materials include wood, which can offer a unique aesthetic and good insulation but may require more effort to build. The choice of material should align with the type of materials you plan to print, the desired level of insulation, and your budget. The choice also impacts the case’s overall lifespan and ease of maintenance.

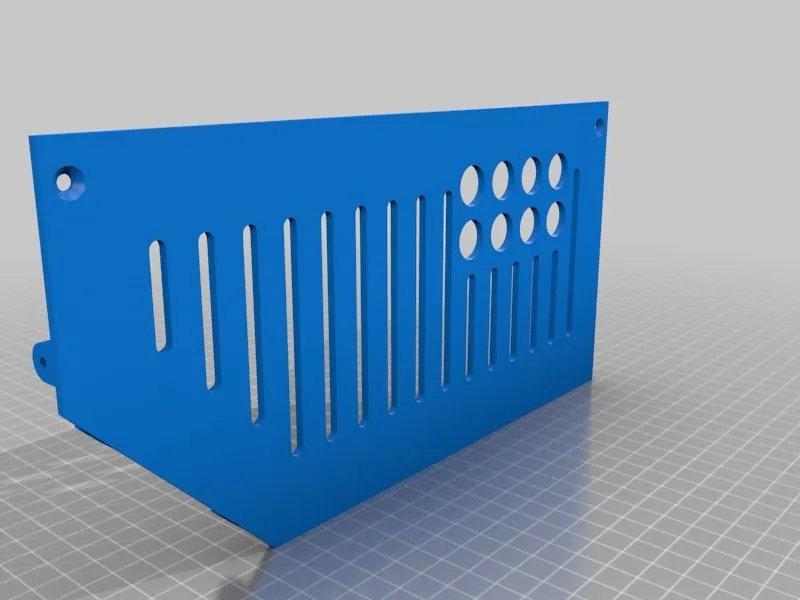

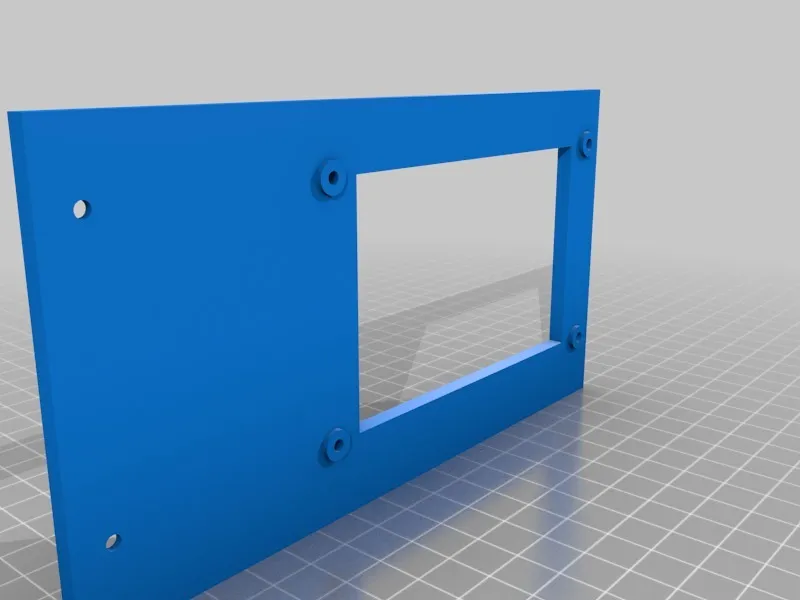

Design Features

The design of your Tevo Tarantula case plays a significant role in its usability and overall effectiveness. Key design considerations include accessibility, ventilation, and ease of assembly. Look for features such as hinged doors or removable panels that allow easy access to the printer for maintenance or adjustments. Ventilation is critical, and the case should incorporate vents or openings to allow for proper airflow, preventing overheating. Consider the placement of these vents to minimize drafts and ensure a consistent internal temperature. Additionally, the design should be easy to assemble and disassemble, allowing for convenient maintenance and upgrades. Some cases come with pre-cut holes for cable management, and mounting options for accessories like filament holders or LED lighting, adding to the overall functionality and user experience. Carefully assess these design features to ensure the case meets your specific needs and provides a seamless 3D printing experience.

Heating and Temperature Control

Effective heating and temperature control are essential aspects of a Tevo Tarantula case, particularly when printing with materials that are sensitive to temperature fluctuations. By maintaining a consistent internal temperature, the case helps to prevent warping, improve layer adhesion, and ensure the overall success of your prints. This control can be achieved through passive or active methods. Passive methods rely on the insulating properties of the case materials to trap heat generated by the printer. Active methods involve the use of heaters and temperature sensors to maintain a specific temperature within the enclosure. The choice between these methods will depend on the materials you primarily print with and your desired level of control. The ability to regulate and maintain a consistent temperature is crucial for achieving high-quality prints, as it minimizes the impact of external factors and allows for optimal material performance.

Temperature Consistency

Achieving temperature consistency within your Tevo Tarantula case is a key factor in the quality of your prints. The goal is to maintain a stable thermal environment, minimizing fluctuations that can lead to printing defects. This consistency is achieved through a combination of insulation, ventilation, and, in some cases, active heating. Proper insulation, provided by the case materials, helps to retain heat generated by the printer and the heated bed. Ventilation, if present, must be carefully managed to prevent drafts that could disrupt the temperature balance. If using active heating, precise temperature control is crucial, often achieved through sensors and thermostats that regulate the heater. Furthermore, the internal design should promote even heat distribution, avoiding hotspots or cold spots that could affect the printing process. By focusing on temperature consistency, you’ll ensure better adhesion between layers, reduce warping, and enhance the overall quality of your prints, regardless of the ambient conditions.

Preventing Warping and Delamination

Warping and delamination are common issues in 3D printing, particularly with materials that tend to shrink as they cool. A Tevo Tarantula case plays a vital role in preventing these defects by creating a stable thermal environment. By maintaining a consistent temperature, the case minimizes the temperature gradients that can cause stress within the printed object, leading to warping. The enclosure helps to regulate the cooling rate of the material, allowing it to cool down evenly and preventing the formation of internal stresses that could cause the layers to separate, which is referred to as delamination. For materials like ABS and Nylon, which are highly susceptible to warping, a case is indispensable. The enclosed environment allows for better adhesion between layers. By effectively controlling the temperature and cooling process, the Tevo Tarantula case helps to reduce the likelihood of these common issues. The user is thereby able to produce dimensionally accurate and structurally sound prints.

Assembly and Installation Tips

Proper assembly and installation are essential for ensuring the effective performance of your Tevo Tarantula case. Follow the manufacturer’s instructions carefully. Ensure all components are securely fastened. Before starting, lay out all parts and familiarize yourself with the included hardware and instructions. When assembling the case, pay close attention to the alignment of panels and the tightness of screws, as these factors can affect the structural integrity and functionality of the enclosure. Ensure adequate ventilation. Once assembled, carefully position your Tevo Tarantula printer inside the case, ensuring that there is enough clearance around all moving parts. The placement should also consider cable management to prevent interference and ensure neatness. Following these assembly and installation tips will help you create a functional and effective enclosure that will maximize your printing success.

Step-by-Step Guide

Here’s a simplified step-by-step guide to help you assemble your Tevo Tarantula case. First, carefully unpack all the components and check the inventory against the parts list provided in the instructions. Next, assemble the frame or base of the enclosure, following the diagrams and securing the panels together with the provided screws or fasteners. Install the side panels, ensuring they fit snugly and align correctly with the frame. If your case has a door or lid, install the hinges and attach the door or lid to the frame, making sure it opens and closes smoothly. Add any additional features such as ventilation fans or LED lighting. Once the case is fully assembled, carefully position your Tevo Tarantula printer inside, ensuring there is adequate space for movement and operation. Finally, connect any necessary cables and power cords, and perform a test run to ensure the case functions correctly and the printer operates without any obstructions. Following this guide will help you set up your case efficiently, and make your printing experience better.

Troubleshooting Common Issues

Even with a well-designed Tevo Tarantula case, you may encounter occasional issues. The ability to troubleshoot common problems is crucial for maintaining a smooth printing experience. Knowing how to diagnose and resolve issues like overheating, poor adhesion, and other printing defects will help you optimize your setup. By understanding the potential causes and implementing the appropriate solutions, you can minimize downtime and ensure consistently high-quality prints. Troubleshooting is part of the learning process, and with a little practice, you can effectively address any challenges you might face and keep your 3D printing workflow efficient and productive. Be sure to follow the printer and case instructions. You can also find a lot of information online through forums.

Overheating Problems

Overheating is a potential issue when using a Tevo Tarantula case, especially with materials that require higher printing temperatures. If you notice signs of overheating, such as filament melting prematurely or print quality deteriorating, you will need to address it promptly. The first step is to monitor the internal temperature of the enclosure using a thermometer. If the temperature is too high, increase ventilation by opening vents or adding a fan. Adjust the printer’s settings to reduce the hotend temperature or slow down the print speed to help cool down the filament. In some cases, you may need to upgrade the case to provide better ventilation or install a temperature controller to regulate the internal temperature. Overheating can lead to a variety of printing problems and potentially damage your printer. Identifying and addressing overheating problems is vital for maintaining optimal printing performance.

Poor Adhesion

Poor adhesion, where the initial layers of your print do not stick properly to the build plate, is another common issue that a Tevo Tarantula case can help address, but sometimes may also contribute to. While the case helps maintain a consistent temperature, if the build plate temperature is too low or if there’s a draft inside the case, it can still cause adhesion problems. Ensure your build plate is clean and level. Before each print, wipe the build plate with isopropyl alcohol to remove any residue. Check that the build plate temperature is correct for the filament. For instance, ABS typically requires a higher build plate temperature than PLA. If adhesion continues to be a problem, consider using an adhesion aid like glue stick or hairspray on the build plate. Another option is to use a brim or raft in the print settings, which can improve adhesion.

Maintenance and Care

Regular maintenance and care are crucial for extending the lifespan and ensuring the optimal performance of your Tevo Tarantula case. Performing routine checks, cleaning the case regularly, and inspecting its components will help prevent potential issues and keep your setup running smoothly. By investing a little time in maintenance, you can avoid costly repairs and maintain a high-quality printing environment. Proper care also ensures the long-term effectiveness of the case and contributes to the longevity of your 3D printer. Maintenance will improve your printing experience overall. Regular inspection will allow you to catch problems before they become major.

Cleaning Your Case

Cleaning your Tevo Tarantula case is an essential maintenance task. Dust and debris can accumulate inside the enclosure, potentially affecting print quality and the performance of the printer. Regularly wipe down the interior and exterior surfaces with a soft, damp cloth. Be sure to clean any ventilation vents or fans, as dust buildup can reduce their effectiveness. If your case has clear panels, clean them with a suitable cleaner to maintain visibility. When cleaning, avoid using harsh chemicals or abrasive materials that could damage the case. Regular cleaning not only maintains the appearance of your enclosure but also ensures a clean and safe environment for your 3D printing projects. Clean your case every month.

Regular Inspections

Regular inspections are a crucial part of maintaining your Tevo Tarantula case and identifying potential issues before they escalate. During inspections, look for any signs of wear and tear, such as loose screws, cracks in the panels, or damage to the hinges or door latches. Check the condition of any ventilation fans and ensure they are operating correctly. If your case has internal lighting, check for any burned-out bulbs or loose connections. Pay attention to the condition of the power cords and cables. Addressing small issues promptly will prevent them from developing into more significant problems that could affect print quality or even cause safety hazards. By conducting regular inspections, you can ensure your Tevo Tarantula case remains in optimal condition, and you can continue to enjoy a reliable and high-performing 3D printing setup. Check your enclosure every three months.

Tevo Tarantula Case Frequently Asked Questions

Many 3D printing enthusiasts have questions about Tevo Tarantula cases. Here are answers to some frequently asked questions. Can I build my own Tevo Tarantula case? Yes, you can build your own case to suit your requirements. What materials are best for a Tevo Tarantula case? The best materials are acrylic, polycarbonate, and wood. Does a Tevo Tarantula case reduce noise? Yes, the case can significantly reduce noise. Does a Tevo Tarantula case help with fumes? Yes, the case will help to contain the fumes. Are Tevo Tarantula cases difficult to assemble? No, most cases are easy to assemble. Are there any safety concerns? Yes, it’s always important to monitor the machine during printing.

Where to Buy a Tevo Tarantula Case

You can find Tevo Tarantula cases from various online retailers and specialized 3D printing stores. Amazon is a popular choice, offering a wide selection of cases from different manufacturers. Other online retailers, such as eBay and AliExpress, also offer a range of options. Local 3D printing stores often carry enclosures and can provide expert advice. When purchasing, consider the materials and design that best suit your needs. Check reviews to ensure that the case is well-made and meets your expectations. Comparing prices, and shipping options will help you make the best decision. You may also find other resources online that provide recommendations. By exploring these options, you can find the perfect Tevo Tarantula case to improve your printing experience.