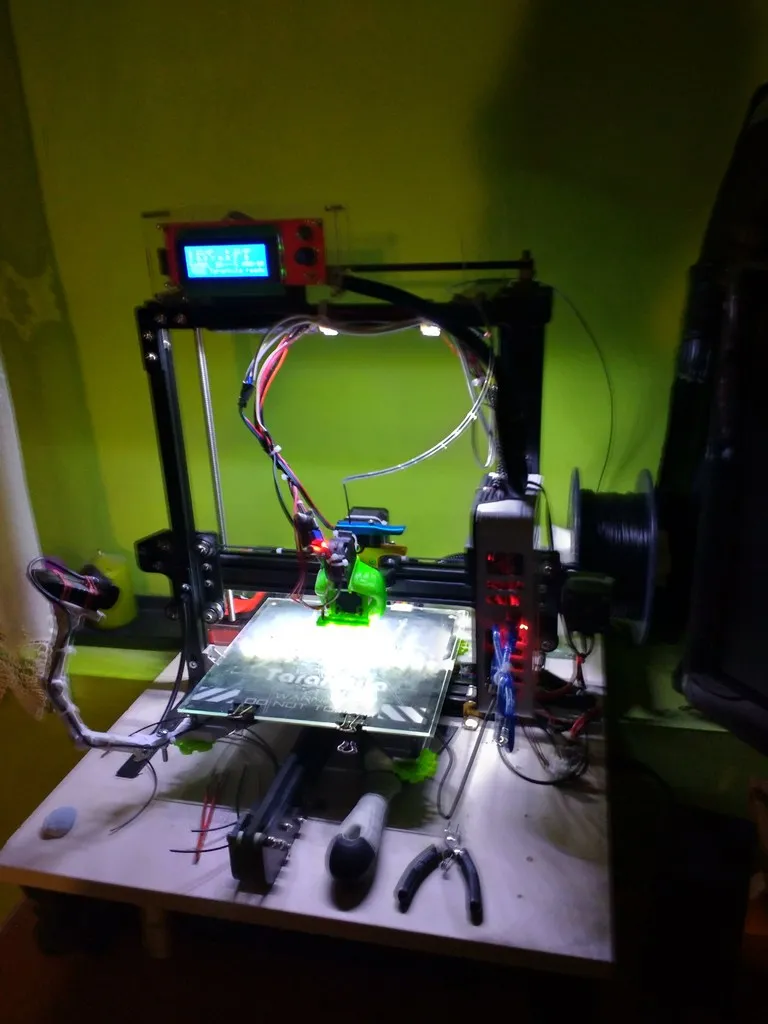

Tevo Tarantula Extruder Motor Troubleshooting

Experiencing issues with your Tevo Tarantula’s extruder motor is a common problem that can halt your 3D printing projects. This guide provides a comprehensive troubleshooting approach to diagnose and fix the problem. A malfunctioning extruder motor prevents filament from being fed into the hot end, leading to failed prints or incomplete layers. By systematically examining potential causes, from power supply problems to mechanical obstructions, you can identify the root cause and restore your printer’s functionality. This guide is designed to help you understand the common issues and implement effective solutions, saving you time and frustration.

Possible Causes for Extruder Motor Failure

Several factors can contribute to the failure of your Tevo Tarantula’s extruder motor. Understanding these potential causes is the first step in effective troubleshooting. Issues range from electrical problems, such as a faulty power supply or motor driver, to mechanical hindrances like filament jams. Firmware configuration errors and wiring problems can also lead to motor malfunction. Identifying the precise cause is crucial for implementing the correct fix. This section dives into the most common causes, setting the stage for a detailed investigation of each area.

Power Supply Issues

The power supply provides the necessary electrical current to operate the extruder motor. If the power supply is failing or not delivering the correct voltage, the motor will not function correctly. Power supply problems can manifest in various ways, including intermittent operation, complete motor failure, or even unusual noises. Ensure the power supply is appropriately sized for your printer’s components and that the connections are secure. Check the power supply’s output voltage with a multimeter to verify it matches the specifications for your Tevo Tarantula.

Check the Voltage Settings

Incorrect voltage settings can damage the extruder motor or prevent it from operating. The motor driver and the motor itself are designed to work within a specific voltage range. Ensure that the power supply is set to the correct voltage, typically 12V or 24V, depending on your printer’s configuration. Double-check the settings on the power supply itself and confirm that it matches the specifications for the printer’s components. Incorrect voltage can cause under-powering or over-powering of the motor, leading to failures or reduced lifespan. Proper voltage settings are critical for optimal performance.

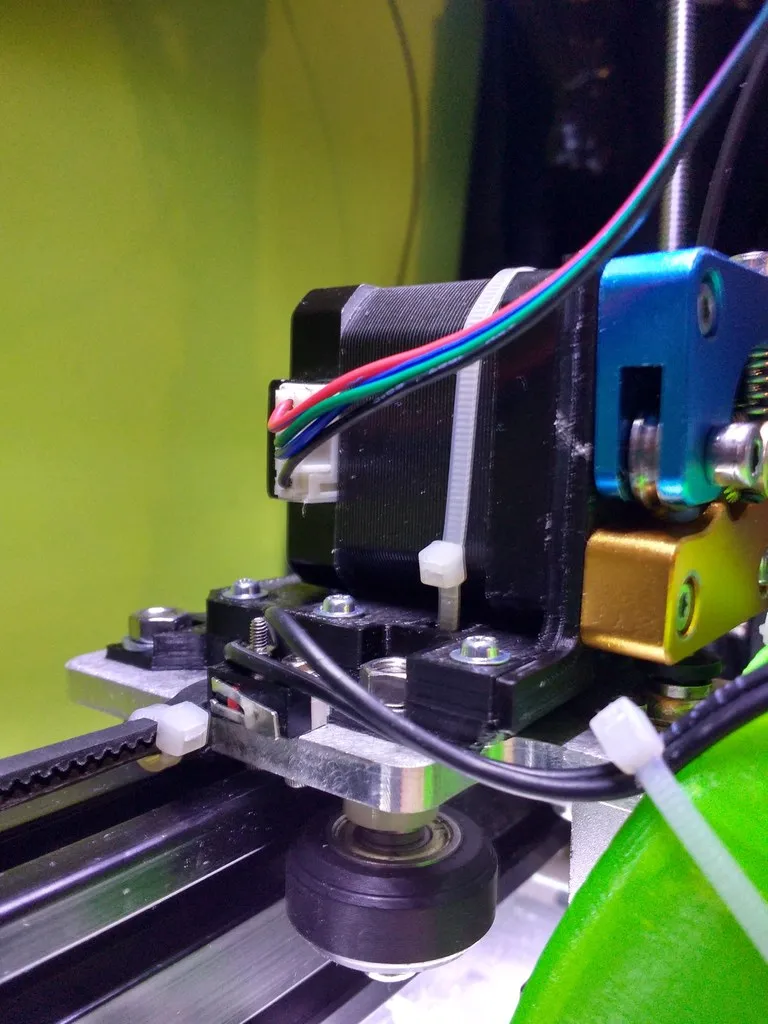

Motor Driver Issues

The motor driver is responsible for controlling the current flow to the extruder motor. If the driver malfunctions, the motor may not receive the signals it needs to operate. Common issues include overheating, short circuits, or damage from voltage spikes. Symptoms of a bad motor driver include complete motor failure, erratic motor movements, or the motor making unusual noises. Motor drivers are often mounted on the mainboard. Identifying a faulty driver often involves visual inspection for signs of damage, such as burnt components or physical damage. Replacing the motor driver can often resolve these problems.

Inspect the Motor Driver Board

Carefully inspect the motor driver board for any signs of damage. Look for burnt components, cracked solder joints, or loose connections. Overheating can also damage the driver, so check for discoloration or any indications of excessive heat. If you find visible damage, the driver board likely needs to be replaced. A multimeter can also be used to test the continuity and resistance of the components. However, a visual inspection often provides the most immediate clues. Replacing a faulty motor driver board can restore proper function to the extruder motor and get your printer back in operation.

Software/Firmware Problems

Incorrectly configured firmware can also cause the extruder motor to malfunction. The firmware controls the motor’s behavior, including its direction, speed, and current settings. Issues such as incorrect step settings, reversed motor direction, or disabled motor drivers within the firmware can prevent the extruder motor from operating correctly. Checking the firmware settings is a critical step. Ensure that the correct motor type, step settings, and motor direction are configured. If you recently updated the firmware, consider reverting to a previous version to see if the problem persists. The correct firmware configuration ensures that the motor receives the appropriate commands to function efficiently.

Check the Firmware Configuration

Access your printer’s firmware settings through the LCD screen or by connecting to a computer. Navigate through the settings to ensure the motor driver’s parameters are correctly configured. Verify the motor’s steps per millimeter (steps/mm) setting, which determines how far the extruder motor moves the filament per step. If this setting is incorrect, the motor will either over-extrude or under-extrude. Also, check the motor direction setting to ensure the motor is turning in the correct direction. Incorrect settings may cause the motor to rotate backwards, or not at all. It’s essential to ensure all settings are accurate to prevent motor failure.

Extruder Motor Wiring

Damaged or loose wiring can disrupt the electrical connection to the extruder motor. This can result in intermittent operation or complete motor failure. Problems with the wiring might arise from vibration, wear and tear, or improper connections. Inspect the wiring between the motor and the mainboard for any breaks, loose connections, or shorts. Carefully trace the wires from the motor to the mainboard and examine the connectors for any signs of damage. Wiring issues are often easy to overlook but can cause significant problems. Ensure the connections are secure and the wires are intact for reliable motor operation.

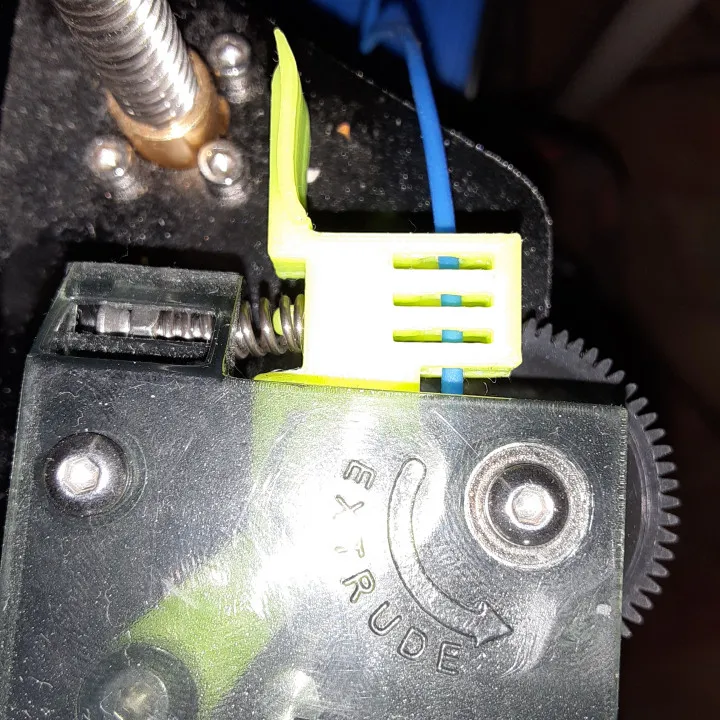

Inspect Wiring Connections

Visually inspect the wiring connections at both the extruder motor and the mainboard. Make sure the connectors are securely plugged in and that there are no loose wires. Gently tug on each wire to ensure it is properly connected. Examine the wires for any signs of damage, such as cuts, fraying, or exposed conductors. If you find any damaged wires, replace them immediately. Secure wiring connections are essential for stable and reliable electrical contact. Incorrect wiring can lead to motor failure or erratic movements, so double-check these connections to eliminate potential issues.

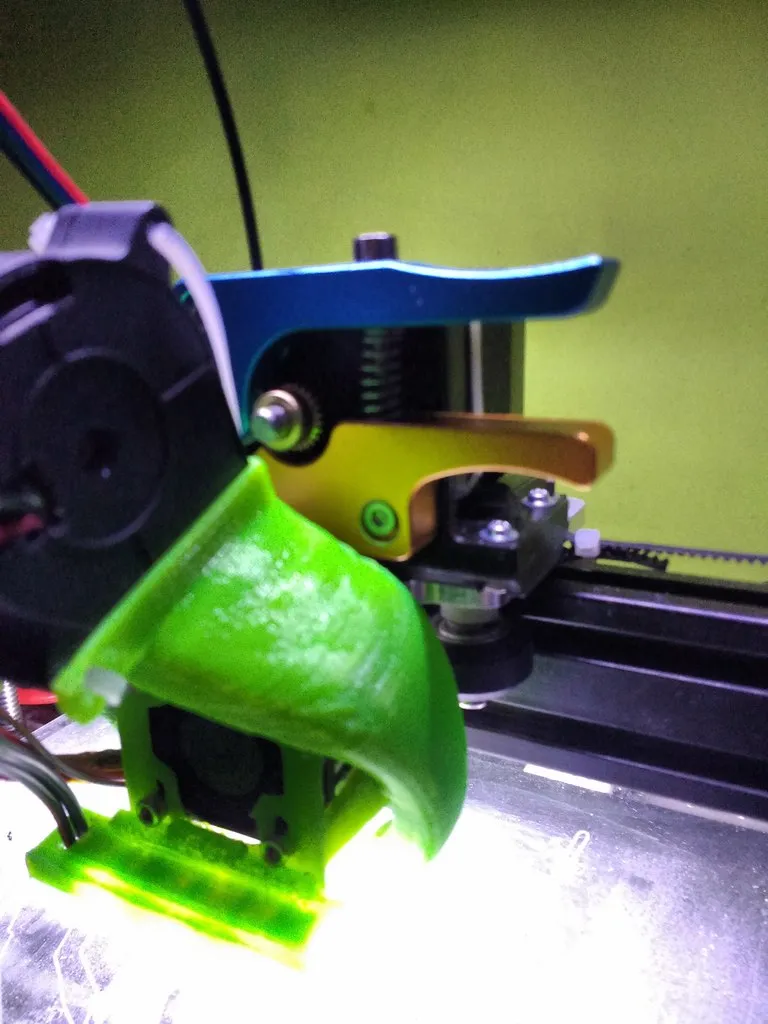

Mechanical Obstructions

Mechanical obstructions within the extruder assembly can prevent the motor from functioning correctly. Filament jams, blockages in the hot end, or binding in the filament path all contribute to motor failure. If the motor encounters excessive resistance, it may stall, overheat, or fail to move the filament. Regular maintenance is essential. Check the extruder for any signs of obstructions, and clear them before trying to print again. Over time, filament debris or other materials can clog the nozzle or the filament path. Resolving mechanical obstructions is critical for keeping the extruder motor running smoothly and preventing printing failures.

Check for Filament Jams

Filament jams are a common cause of extruder motor problems. They occur when the filament gets stuck within the hot end, nozzle, or extruder assembly. To check for a jam, heat up the hot end to the printing temperature and try to manually push the filament through. If the filament resists, there is a jam. You can try using a needle or a specialized tool to clear the blockage. Alternatively, consider disassembling the hot end to clean it thoroughly. Regular inspection of the nozzle and filament path can help prevent filament jams. A clean and clear filament path is essential for consistent printing.

Troubleshooting Steps

When your Tevo Tarantula’s extruder motor isn’t working, follow a systematic approach to diagnose the problem. Begin with the simplest checks and proceed to more complex troubleshooting steps. This methodical approach helps you efficiently pinpoint the source of the issue and prevents wasted time. Starting with the basic checks, like power supply and wiring, is often the quickest route to the solution. Addressing the problem in a structured way helps you avoid unnecessary repairs and get your printer back in operation quickly.

Step 1 Check the Power Supply

Ensure that the power supply is turned on and providing the correct voltage. Use a multimeter to check the output voltage of the power supply, comparing it to the printer’s specifications. If the voltage is incorrect, the power supply may be faulty and need replacing. Check the power supply connections to ensure they are secure. A loose connection could cause intermittent operation or complete failure of the motor. Make sure the power supply is appropriate for the components it is powering; underpowered supplies can cause problems. Verifying power supply integrity is a fundamental step in any troubleshooting process.

Step 2 Examine the Motor Driver

Visually inspect the motor driver on the mainboard for any signs of damage. Look for burnt components, cracks, or loose solder joints. Check the motor driver’s heat sink; excessive heat can indicate a problem. Ensure the heat sink is properly attached. If you find any damage, the motor driver may need to be replaced. Before replacing, verify the connections and consult your printer’s manual for correct motor driver specifications. Damaged motor drivers can prevent the motor from receiving the signals it needs to function correctly. Inspecting the motor driver is an essential troubleshooting step.

Step 3 Review the Firmware

Access the printer’s firmware settings to verify the motor driver configuration. Ensure that the correct motor type and step settings are configured. Confirm the motor direction setting. Check the motor’s steps per millimeter (steps/mm), which must be accurate for proper filament extrusion. Incorrect settings may cause the motor to malfunction or not extrude filament. Firmware settings are critical for proper motor operation. Update the firmware if necessary or consider reverting to a previous version. Reviewing the firmware is an essential step when troubleshooting motor-related issues.

Step 4 Inspect the Wiring

Carefully inspect the wiring connections at both the extruder motor and the mainboard. Check for loose connections, frayed wires, or any signs of damage. A loose connection can interrupt the signal to the motor, while damaged wiring can cause a short circuit or prevent the motor from operating. Gently tug on each wire to ensure it is securely connected. If you find damaged wires, replace them immediately. Proper wiring is essential for reliable and stable motor performance. Pay special attention to wiring connections to eliminate any electrical problems. Ensure that the connections are secure.

Step 5 Look for Mechanical Issues

Examine the extruder assembly for any mechanical obstructions, such as filament jams or debris. Heat up the hot end and attempt to manually push the filament through. If there’s resistance, there may be a blockage in the nozzle or the filament path. Use a cleaning needle or disassemble the hot end for a thorough cleaning. Check the filament for any signs of entanglement or damage. Mechanical obstructions can prevent the motor from turning, leading to printing failures. Removing mechanical obstructions is a critical step in troubleshooting motor-related issues.

Preventative Maintenance for Extruder Motors

Regular maintenance can prevent extruder motor problems. Implement these preventative measures to keep your 3D printer running smoothly. Regular maintenance saves time and ensures reliable performance. It prevents potential failures by addressing issues before they become critical. Following the recommendations below will keep your Tevo Tarantula’s extruder motor running at peak performance.

- Keep the printer clean by removing dust and debris.

- Lubricate moving parts regularly to reduce friction.

- Use high-quality filament to reduce jams and clogs.

- Store filament in a dry place to prevent moisture absorption.

- Perform routine inspections of wiring and connections.

- Check the extruder assembly for wear and tear.

- Regularly tighten any loose screws.

- Monitor the extruder motor for any unusual noises.